Nevada Copper’s Roadmap to Production

September 7, 2018

As you know, we have now moved out of the pre-works phase and right into full construction at the underground mine project at Pumpkin Hollow.

The pre-works phase was rigorous. Large, highly-skilled teams worked tirelessly on site in order to complete a variety of key tasks.

In addition, new staff were hired, numerous safety and site induction sessions were run and a great deal of community engagement took place.

The construction phase is a very busy and very exciting time for a company and I’d like to give you the bird’s eye view of the steps that will occur between now and when we enter production in 2019.

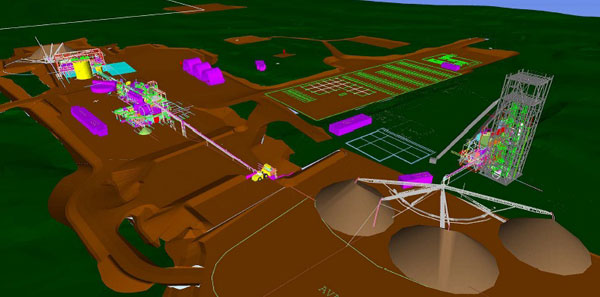

There are two main areas of focus for the upcoming activity: the underground mine and the processing facility. A lot of the work will be carried out concurrently so that we can enter production in 2019. Here then, is a snapshot of what’s coming up:

Underground Mine

- Finish sinking the East/South main shaft to the 1990 ft level and then to the 2090 ft level

- Carry out lateral development at both the 1990 ft and 2090 ft levels

- Begin Alimak raise from the 1990 level to the 1300ft level

- Carry out the engineering and procurement for east north ventilation shaft;

- From surface, sink another shaft down to 1300 ft to intersect the Alimak raise

Once the East North ventilation shaft is established it can be used to hoist men, materials and ore to the surface. Concurrently, we will then finish sinking the East Main shaft to the 2147 ft level and install the steel infrastructure, service hoist, auxiliary hoist and production hoist upgrades required for production.

Processing Facility

Concurrently with shaft sinking and underground development, the bulk earth works will commence for the surface processing facility and associated works.

The surface works will include construction of:

- Ore and waste stacking conveyance system from the headframe to stockpiles;

- Crushing and grinding circuit;

- Flotation and Thickening circuit;

- Filtering circuit;

- Dry stack waste disposal;

- Concentrate loading facility;

- Pastefill plant to return waste underground and fill open cuts;

- All electrical, instrumentation and communications equipment; and

- Parking, administrative buildings and maintenance facilities.

All the above surface infrastructure is designed to accommodate a minimum of 5,000 short tons per day of production.

Pumpkin Hollow will be in an almost constant state of change in the coming months as we complete the steps (and others) that I’ve outlined. Be sure to sign up to our email database as we will be sharing photos, videos and more blog posts of our progress as we move forward. In the meantime, I’ll leave you with some still shots from our 3D animation of the planned site infrastructure.

Matt Gili, CEO of Nevada Copper